The circuit that you will be constructing holds six sensors

that will interface to the robot that you will be building throughout the

semester. Their are four light sensors, and two touch sensors. All

of the sensors feed into a connector that will later be tied into your robot.

Optical Sensor

The optical sensors are made from Cadmium Sulfide, or

CdS. The cell consists of a thin line of CdS that goes between two

terminals. As light hits the Cadmium Sulfide electrons are dislodged

within the material and become free to carry current, thereby lowering the

material's resistance. The CdS cell is put into a circuit in series

with a 5 volt source and a resistor as shown. The circuit may

look a little funny because there is not a complete loop, but this is

OK. The drawing uses a convention that has a 5 volt source implicitly

in the circuit between the nod labeled "+5V" and the node labeled

"Ground."

The optical sensors are made from Cadmium Sulfide, or

CdS. The cell consists of a thin line of CdS that goes between two

terminals. As light hits the Cadmium Sulfide electrons are dislodged

within the material and become free to carry current, thereby lowering the

material's resistance. The CdS cell is put into a circuit in series

with a 5 volt source and a resistor as shown. The circuit may

look a little funny because there is not a complete loop, but this is

OK. The drawing uses a convention that has a 5 volt source implicitly

in the circuit between the nod labeled "+5V" and the node labeled

"Ground."

The current (I) through the circuit is voltage (V=5 volts)

divided by the total resistance, Rtotal=Rresistor+RCdS.

The voltage across the CdS cell is this current times the

resistance of the CdS cell.

So as light hits the CdS cell, its resistance decreases, as

does the voltage across the cell. By monitoring this voltage we can

measure the light hitting the sensor.

This circuit is repeated 4 times on the circuit you will be

constructing, once for each photo-sensor.

Touch Sensor

The touch sensor is a little easier to understand. Its

schematic is shown, and consists of a switch and a resistor. Normally

the switch is closed, so the output voltage is zero volts (Ground).

When the switch opens up, current ceases to flow, so the voltage across the

resistor goes to zero. Since the voltage on both sides of the resistor

is the same, the output voltage becomes 5 volts.

The touch sensor is a little easier to understand. Its

schematic is shown, and consists of a switch and a resistor. Normally

the switch is closed, so the output voltage is zero volts (Ground).

When the switch opens up, current ceases to flow, so the voltage across the

resistor goes to zero. Since the voltage on both sides of the resistor

is the same, the output voltage becomes 5 volts.

There are two of these circuits on your robot, to detect

collisions with objects on either side.

Completed Schematic

A completed schematic is shown below. There are four

light sensor circuits, and two touch sensors (a different circuit symbol is

used for the touch switches, but it is functionally equivalent to the one

shown above). All of the signals, including +5 volts and ground, then

go to a connector (labeled DIP14HEADER) which

will feed the signals to the computer on your robot. This diagram

doesn't show resistors connected to the switches because these are actually

on the board that holds the computer.

Your going to be constructing this circuit using a printed

circuit board, or PCB. The PCB is a thin insulating board onto which a

circuit is printed. You then connect your components to the circuit with

solder. Solder is a combination of metals, usually 60% lead/40% tin,

that is melted with a soldering iron to connect electrical

components. The solder melts at about 190°C (370°F).

It has a core of flux which is seen boiling away as the solder is

applied -- the flux is a chemical that improves the quality of the connection

being made. If you haven't soldered before, please read my

page that describes soldering (and perhaps check out some of the links at

the bottom of that page). Solder contains lead, so try to avoid

breathing the fumes, and wash your hands when you are done. If you are

experienced in soldering, let somebody else in the group (with less

experience) do the soldering while you try to help them learn the proper

technique.

The

diagram shows the layout of the printed circuit board. The green line

represent traces (copper lines that are printed on the board, then covered

with solder to prevent oxidation) on the top side of the board -- called the

component side. The red lines represent traces on the bottom side --

called the solder side. On this layout you can see where the switches

(S1 and S2), the CdS cells, the resistors and the 14 pin connector are placed.

The

diagram shows the layout of the printed circuit board. The green line

represent traces (copper lines that are printed on the board, then covered

with solder to prevent oxidation) on the top side of the board -- called the

component side. The red lines represent traces on the bottom side --

called the solder side. On this layout you can see where the switches

(S1 and S2), the CdS cells, the resistors and the 14 pin connector are placed.

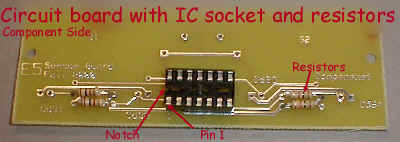

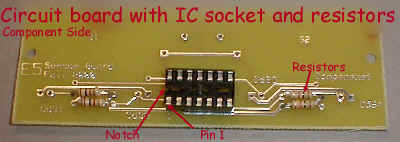

To start the

construction place the 14 pin socket and four 1000 ohm resistors on the board

with the component side (with most of the writing) facing up, as shown.

Solder all the components, and cut the leads of the resistors close to the

board. There should be a completed board to which you can compare yours

board.

To start the

construction place the 14 pin socket and four 1000 ohm resistors on the board

with the component side (with most of the writing) facing up, as shown.

Solder all the components, and cut the leads of the resistors close to the

board. There should be a completed board to which you can compare yours

board.

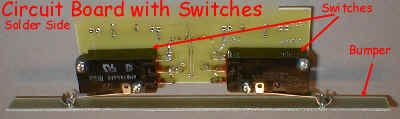

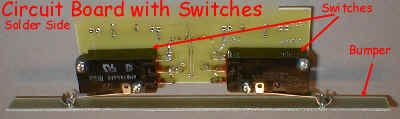

Next,

screw two switches to the solder side of the board with four 3/4" #4-40

screws. The 3/4" corresponds to the length of the screw, #4 refers

to the diameter, and 40 refers to the size of the thread (40 per inch).

Next feed a wire up through one of the holes under one of the three terminals

on on one of the switches, and hook it onto the terminal. Solder

both ends of this wire. Repeat with the other terminals until all six

terminals are soldered. Attach the bumper as shown by placing wires

through the holes, and twisting the wires around the leaves of the switches

(thin bus wire works well). Don't attach too firmly; the switches should

have a little play, but the should be in no danger of falling off.

Next,

screw two switches to the solder side of the board with four 3/4" #4-40

screws. The 3/4" corresponds to the length of the screw, #4 refers

to the diameter, and 40 refers to the size of the thread (40 per inch).

Next feed a wire up through one of the holes under one of the three terminals

on on one of the switches, and hook it onto the terminal. Solder

both ends of this wire. Repeat with the other terminals until all six

terminals are soldered. Attach the bumper as shown by placing wires

through the holes, and twisting the wires around the leaves of the switches

(thin bus wire works well). Don't attach too firmly; the switches should

have a little play, but the should be in no danger of falling off.

The last step is

to attach the photocells. Take several photo-cells and measure their

resistance, which should decrease as more light falls upon them. Go

through them, one at a time, until you find four that have similar resistance

when point in the same direction (so that the same amount of light falls on

each). You won't be able to get a really close match, but shoot for the

same value within about 20-30% -- the match isn't critical, or even totally

necessary. Slip a 7/8" length of shrink wrap tubing on on

leg. Carefully insert the leads of the photocell from

the component side, until the shrink wrap butts up against the PCB. Hold

the photocell there,

and solder. Hold the photocell by the top part, the leads will get very

hot as you solder them (metal conducts heat very well). Repeat until all

4 are attached. When finished, cut the excess leads off from the back of

the PCB.

The last step is

to attach the photocells. Take several photo-cells and measure their

resistance, which should decrease as more light falls upon them. Go

through them, one at a time, until you find four that have similar resistance

when point in the same direction (so that the same amount of light falls on

each). You won't be able to get a really close match, but shoot for the

same value within about 20-30% -- the match isn't critical, or even totally

necessary. Slip a 7/8" length of shrink wrap tubing on on

leg. Carefully insert the leads of the photocell from

the component side, until the shrink wrap butts up against the PCB. Hold

the photocell there,

and solder. Hold the photocell by the top part, the leads will get very

hot as you solder them (metal conducts heat very well). Repeat until all

4 are attached. When finished, cut the excess leads off from the back of

the PCB.

Attach

the bumper loosely to the two switches using buss wire. The completed board (attached to the robot) is shown . A

larger photo of the whole robot (as seen from

below), is also available.

Attach

the bumper loosely to the two switches using buss wire. The completed board (attached to the robot) is shown . A

larger photo of the whole robot (as seen from

below), is also available.

The optical sensors are made from Cadmium Sulfide, or CdS. The cell consists of a thin line of CdS that goes between two terminals. As light hits the Cadmium Sulfide electrons are dislodged within the material and become free to carry current, thereby lowering the material's resistance. The CdS cell is put into a circuit in series with a 5 volt source and a resistor as shown. The circuit may look a little funny because there is not a complete loop, but this is OK. The drawing uses a convention that has a 5 volt source implicitly in the circuit between the nod labeled "+5V" and the node labeled "Ground."

The touch sensor is a little easier to understand. Its schematic is shown, and consists of a switch and a resistor. Normally the switch is closed, so the output voltage is zero volts (Ground). When the switch opens up, current ceases to flow, so the voltage across the resistor goes to zero. Since the voltage on both sides of the resistor is the same, the output voltage becomes 5 volts.

The

diagram shows the layout of the printed circuit board. The green line

represent traces (copper lines that are printed on the board, then covered

with solder to prevent oxidation) on the top side of the board -- called the

component side. The red lines represent traces on the bottom side --

called the solder side. On this layout you can see where the switches

(S1 and S2), the CdS cells, the resistors and the 14 pin connector are placed.

The

diagram shows the layout of the printed circuit board. The green line

represent traces (copper lines that are printed on the board, then covered

with solder to prevent oxidation) on the top side of the board -- called the

component side. The red lines represent traces on the bottom side --

called the solder side. On this layout you can see where the switches

(S1 and S2), the CdS cells, the resistors and the 14 pin connector are placed. To start the

construction place the 14 pin socket and four 1000 ohm resistors on the board

with the component side (with most of the writing) facing up, as shown.

Solder all the components, and cut the leads of the resistors close to the

board. There should be a completed board to which you can compare yours

board.

To start the

construction place the 14 pin socket and four 1000 ohm resistors on the board

with the component side (with most of the writing) facing up, as shown.

Solder all the components, and cut the leads of the resistors close to the

board. There should be a completed board to which you can compare yours

board. Next,

screw two switches to the solder side of the board with four 3/4" #4-40

screws. The 3/4" corresponds to the length of the screw, #4 refers

to the diameter, and 40 refers to the size of the thread (40 per inch).

Next feed a wire up through one of the holes under one of the three terminals

on on one of the switches, and hook it onto the terminal. Solder

both ends of this wire. Repeat with the other terminals until all six

terminals are soldered. Attach the bumper as shown by placing wires

through the holes, and twisting the wires around the leaves of the switches

(thin bus wire works well). Don't attach too firmly; the switches should

have a little play, but the should be in no danger of falling off.

Next,

screw two switches to the solder side of the board with four 3/4" #4-40

screws. The 3/4" corresponds to the length of the screw, #4 refers

to the diameter, and 40 refers to the size of the thread (40 per inch).

Next feed a wire up through one of the holes under one of the three terminals

on on one of the switches, and hook it onto the terminal. Solder

both ends of this wire. Repeat with the other terminals until all six

terminals are soldered. Attach the bumper as shown by placing wires

through the holes, and twisting the wires around the leaves of the switches

(thin bus wire works well). Don't attach too firmly; the switches should

have a little play, but the should be in no danger of falling off. The last step is

to attach the photocells. Take several photo-cells and measure their

resistance, which should decrease as more light falls upon them. Go

through them, one at a time, until you find four that have similar resistance

when point in the same direction (so that the same amount of light falls on

each). You won't be able to get a really close match, but shoot for the

same value within about 20-30% -- the match isn't critical, or even totally

necessary. Slip a 7/8" length of shrink wrap tubing on on

leg. Carefully insert the leads of the photocell from

the component side, until the shrink wrap butts up against the PCB. Hold

the photocell there,

and solder. Hold the photocell by the top part, the leads will get very

hot as you solder them (metal conducts heat very well). Repeat until all

4 are attached. When finished, cut the excess leads off from the back of

the PCB.

The last step is

to attach the photocells. Take several photo-cells and measure their

resistance, which should decrease as more light falls upon them. Go

through them, one at a time, until you find four that have similar resistance

when point in the same direction (so that the same amount of light falls on

each). You won't be able to get a really close match, but shoot for the

same value within about 20-30% -- the match isn't critical, or even totally

necessary. Slip a 7/8" length of shrink wrap tubing on on

leg. Carefully insert the leads of the photocell from

the component side, until the shrink wrap butts up against the PCB. Hold

the photocell there,

and solder. Hold the photocell by the top part, the leads will get very

hot as you solder them (metal conducts heat very well). Repeat until all

4 are attached. When finished, cut the excess leads off from the back of

the PCB. Attach

the bumper loosely to the two switches using buss wire. The completed board (attached to the robot) is shown . A

larger

Attach

the bumper loosely to the two switches using buss wire. The completed board (attached to the robot) is shown . A

larger